1. The screw plasticization of melt-blown cloth extrusion equipment is critical, please choose a longer screw with better plasticization;

2. A screen changer needs to be added between the screw of the extruder and the die head (2 layers of 200 mesh fabric);

3. A melt pump (uniform speed feeding) should be added behind the screen changer;

4. Two layers of 200-mesh mesh cloth are placed inside the die head (the new die head should be calcined in vacuum to ensure that there is no pore blockage);

5. The screw temperature setting is 210-230 ℃;

6. The die temperature is set at 220-230 ℃;

7. Hot air temperature setting 280-300 ℃;

8. After the temperature is set, adjust the speed of the host and the size of the hot wind to determine the strength and quality of the cloth;

9. Electret masterbatch and electret equipment must be added;

10. Properly extend the winding distance to allow the cloth to cool down sufficiently.

11. Cloth sealed packaging, work with gloves to avoid direct contact of hands or other conductors with the cloth, reducing the risk of static electricity loss.

Real video

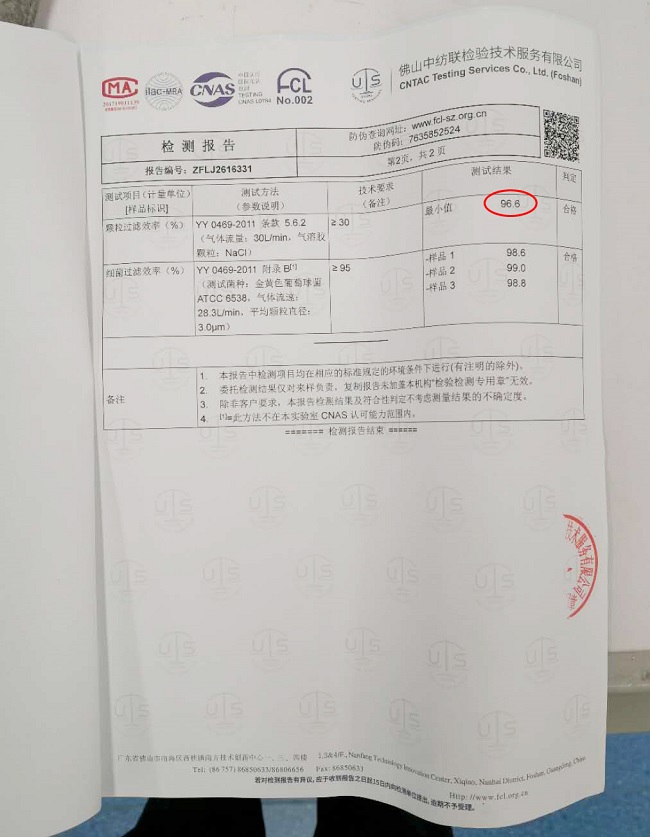

Test Report

The “Special Polypropylene Meltblown Material” independently developed by Huabiao Plastic Technology Co., Ltd. in Shunde District of Foshan City is of excellent quality and stable quality, and is widely praised by users everywhere. Welcome to buy!