HB601-HIPS Flexibilizer

Product features

Type - high molecular weight butadiene terpolymer

Appearance- white irregular particles

Melt index(190℃, 50kg) - 21g/10min

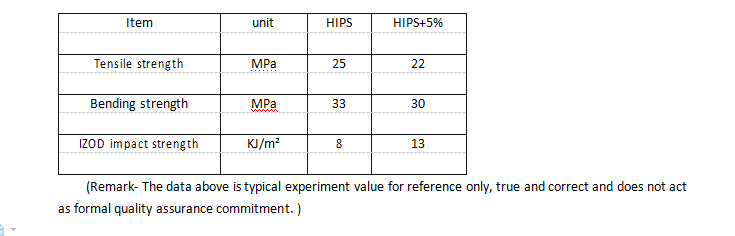

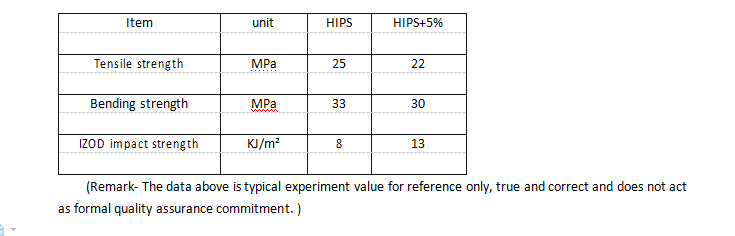

Improving impact strength and tensile elongation at break of HIPS

Solving the product problem of poor toughness, brittle rupture, burst when playing screw

HIPS is improved in impact strength after adding HB601 and the improved HIPS could take the place of ABS outer parts for cost reduction

The glossiness of high glossy HIPS is not affected

Easy to be added and ratio could be adjusted flexibly to solve various of tensile problems Typical data for HIPS resin toughness enhancement

Application area

Dosage

HB202-ABS/HIPS High Gloss Masterbatch

Product description

HB202 consisting of ABS, HIPS flexibilizer binder, specialized dispersant and high gloss spherulite powder, is appropriate for ABS, HIPS resin and for all molding process, such as injection, molding ,extrusion molding, etc

Application characters

High glossiness and toughness

Increasing heat distortion temperature

Good dispersion and excellent compatibility

Improving dimensional stability, reducing buckling deformation and post shrinkage deformation.

Shortening product molding cycle

Reducing material costs

It does not contain brightener and could be applied to products of all kinds of colors flexibly since it is easy to be colored

Conforming to environmental and sanitary requirements of EU ROHS directive

Dosage

Application area

It is appropriate for the injection & extrusion molding process is applied to fields of automobile , home appliance, packaging, profile, etc

Technological condition

The process does not change obviously in extrusion process

The best injection temperature should be above 220℃ when employing HB202 and appropriate backpressure helps to improve the mixing and dispersing between HB202 and target resin