HB901 — Weather Resistant Masterbatch

Characteristics

○Additive amount 2-6%, the concrete additive amount is determined on the basis of product and cost requirements;

○Increasing the aging resistant performance and extending the service life of plastic products;

○Postponing the yellowing of plastic products;

○Preventing the product from losing physical properties;

○The varieties and proportion of weather resistant agent like UV resistant agent, UV absorption agent, antioxidant agent and others are chosen according to the product weather resistant requirements;

○The masterbatch carrier contains ABS, PE, PP, EVA, etc. The concrete type is decided based on the product raw material type and product application.

HB603-Injection Molding Transparent Flexibilizer

Product features

1、Type - high molecular weight butadiene terpolymer

2、Melt index(230℃,2.16Kg)- 20g/10min,Indensity-0.86g/cm3

3、Appearance- Transparent particles

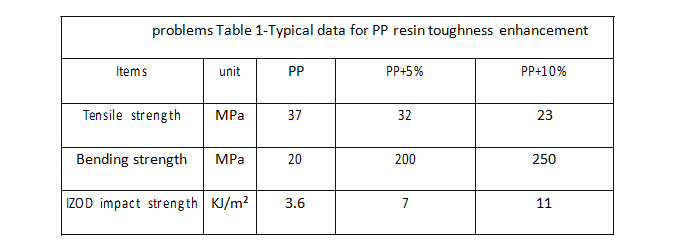

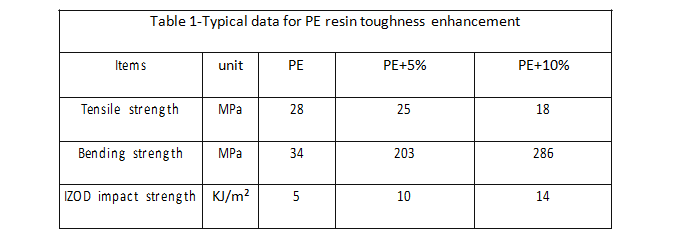

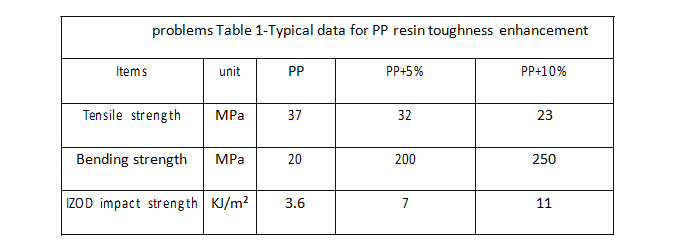

4、Improving impact strength and tensile elongation at break of PP& PE

5、Improving cold resistance property of PP & PE

6、Solving the product problem of poor toughness, brittle rupture, burst when playing screw

7、The glossiness and transparency of PP & PE is not affected

8、Easy to be added and ratio could be adjusted flexibly to solve various of tensile

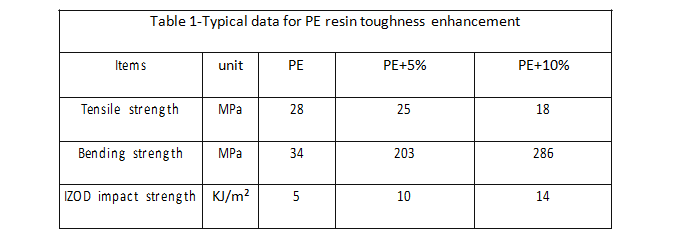

(Remark- The data above is typical experiment value for reference only, true and correct and does not act as formal quality assurance commitment. )

Application area

It is widely used in injection and extrusion products like toys, home appliances, daily necessities, plate extrusion, sheet and so on.

Dosage

The recommended additive amount is 5% and could be regulated according to the product toughness requirement while keeping between 3% and 10%.

Blending process

Mix with raw material and stir evenly with mixing equipment

Technological conditions

No special requirement for injection process. The better the dispersing effect is, the better the toughness is.

Packaging and transportation

It is packed by paper-plastic composite bag with plastic film inside, net weight 25kg/bag. Sharp tools like hasp iron is prohibited during transportation and handling procedure. Means of transport should be kept clean.